ExNihilo

Senior Member

- Joined

- Nov 21, 2008

- Messages

- 1,750

- Reaction score

- 2,789

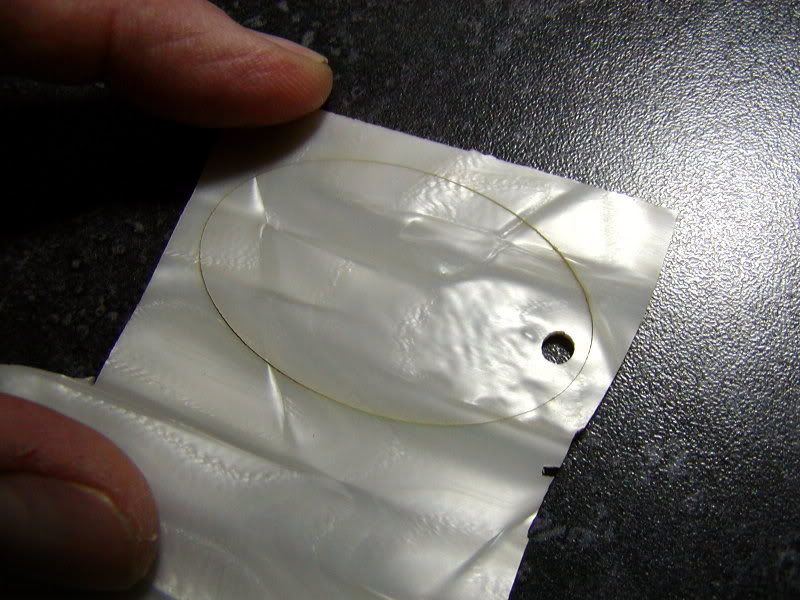

A got a fingerboard from Dave Johnson with his celluloid inlays in it. I would like to age them. Perhaps even make some look shrunken. Do any of you have any ideas as to how to do this and make it look real?

Thank you.

Thank you.