You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Help how to carve the top of the Les Paul.

- Thread starter Mozz

- Start date

This site may earn a commission from merchant affiliate links like Ebay, Amazon, and others.

Murkar

Senior Member

- Joined

- Jul 22, 2010

- Messages

- 1,757

- Reaction score

- 869

Hey Mozz,

You use it to know where to carve steps down; it's difficult to explain in words, so I'm just going to steal this photo from mountain whimsy.

Then you sand down in between the ledges with a power sander, or use a little curved bottom handplane.

You use it to know where to carve steps down; it's difficult to explain in words, so I'm just going to steal this photo from mountain whimsy.

Then you sand down in between the ledges with a power sander, or use a little curved bottom handplane.

emoney

Senior Member

- Joined

- Jan 31, 2010

- Messages

- 7,578

- Reaction score

- 3,974

Go print 8 copies of that plan. Glue them to their own pattern board of whatever material

you want your templates made from. Cut out each line and you'll create, obviously, 8 templates.

Then, use those templates to run your router around them and you'll create the picture that

Murkar just posted. After than, sand it smooth and voila....carved Les Paul.

It really is as simple as that.

you want your templates made from. Cut out each line and you'll create, obviously, 8 templates.

Then, use those templates to run your router around them and you'll create the picture that

Murkar just posted. After than, sand it smooth and voila....carved Les Paul.

It really is as simple as that.

emoney

Senior Member

- Joined

- Jan 31, 2010

- Messages

- 7,578

- Reaction score

- 3,974

What I'm saying is to make templates out of mdf board or plywood of each one of those

topical lines in that drawing. Imagine it as 8 different pieces stacked atop each other.

There are several build threads around here that document the process, I'd read as many

of those as I can.

The larger the bit the better, of course, but it depends on your template more than anything.

As for me, I like the templates to be at least 1/2" thick. You want to take off just a little of

the material at a time, making several passes to get down to the finished depth on the

outer rings so you can avoid tear out. Draw a line on the side of your body to where the

binding should sit and cut upwards from there. Most people use 1/4" as the thinnest, outter

most ring because that's normal binding height.

But, notice I'm saying to make a template and use a pattern bit to cut these steps out.

You can, I suppose, just glue the pattern to the top, but then you'll be freehand so go slowly. The actual math, if I'm not mistaken, is on that pdf you've downloaded where he

shows how deep he made each "ring".

topical lines in that drawing. Imagine it as 8 different pieces stacked atop each other.

There are several build threads around here that document the process, I'd read as many

of those as I can.

The larger the bit the better, of course, but it depends on your template more than anything.

As for me, I like the templates to be at least 1/2" thick. You want to take off just a little of

the material at a time, making several passes to get down to the finished depth on the

outer rings so you can avoid tear out. Draw a line on the side of your body to where the

binding should sit and cut upwards from there. Most people use 1/4" as the thinnest, outter

most ring because that's normal binding height.

But, notice I'm saying to make a template and use a pattern bit to cut these steps out.

You can, I suppose, just glue the pattern to the top, but then you'll be freehand so go slowly. The actual math, if I'm not mistaken, is on that pdf you've downloaded where he

shows how deep he made each "ring".

MRJ5

Senior Member

- Joined

- Jun 13, 2008

- Messages

- 1,582

- Reaction score

- 454

Start reading here: http://www.mylespaul.com/forums/luthiers-corner/124446-exnihilo-vintage-burst-build-4.html#post2419056

Actually go to the beginning of the thread and read twice before you start anything.

When doing a build, you will need a thorough understanding of where you are going before you start doing anything.

Actually go to the beginning of the thread and read twice before you start anything.

When doing a build, you will need a thorough understanding of where you are going before you start doing anything.

MRJ5

Senior Member

- Joined

- Jun 13, 2008

- Messages

- 1,582

- Reaction score

- 454

Thanks, and sorry but for me it is not easy because I do not speak English perfectly, as I understand it I have to create a model like the one in the picture. What height should have the MDF?

View attachment 119954

The thickness of the template doesn't matter. Route the cut as following. (from The link above)

"start this first one at 7/16" deep and raise the router 1/16" for each step."

That will result in 7 contours.

Shandog

Senior Member

- Joined

- May 6, 2011

- Messages

- 356

- Reaction score

- 211

Yeah I use the 3/4" template as well. One thing I would add though is if your using a standard hand router is to make an extra outer template that will sit a little further out to the body edge. Use that first to get that outer edge then go with the first template and not change the height. The template for the first route is pretty far away and your router can tip pretty easily on that outside edge.

Scubaman

Senior Member

- Joined

- Oct 23, 2009

- Messages

- 963

- Reaction score

- 997

Apologies for hijacking the thread (sort of) but how did they carve the tops in the factory back in the 50's? Did they route the steps and then sand or were the tops hand carved from scratch like a hollow body or a violin?

Pete M

Senior Member

- Joined

- Aug 30, 2007

- Messages

- 6,165

- Reaction score

- 9,410

They copy carved them from a master, this left a very rough carved top. They then smoothed them out with a large slack belt sander, which is where the inconsistencies come from. This is as far as I know. It's possible that there were some changes to the dummy along the way it seems.

MRJ5

Senior Member

- Joined

- Jun 13, 2008

- Messages

- 1,582

- Reaction score

- 454

Apologies for hijacking the thread (sort of) but how did they carve the tops in the factory back in the 50's? Did they route the steps and then sand or were the tops hand carved from scratch like a hollow body or a violin?

They copy carved them from a master, this left a very rough carved top. They then smoothed them out with a large slack belt sander, which is where the inconsistencies come from. This is as far as I know. It's possible that there were some changes to the dummy along the way it seems.

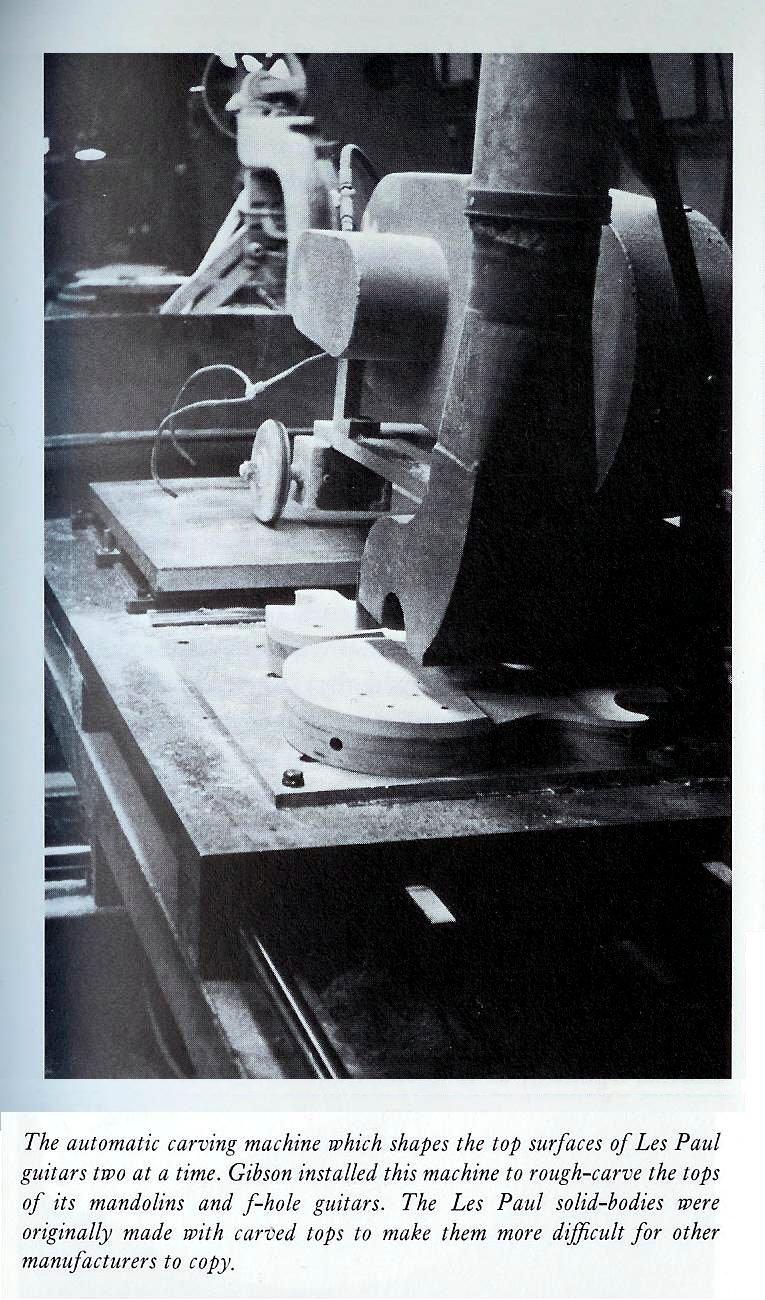

I cannot confirm the years these pictures were taken or the style top being "carved" but they give you the idea how early tops were done.

Those machines use a wheel to follow the master and ganged saw blades remove the wood.

The final picture shows the rough carve on the inset and a worker smoothing the contours with a slack belt sander.

I am confident additional final sanding occurred after the belt sander as well.

rockstar232007

Senior Member

- Joined

- Jun 28, 2008

- Messages

- 18,528

- Reaction score

- 17,747

This is/was that actual machine that Gibson used, though the picture is inverted (the template was on the right side):Apologies for hijacking the thread (sort of) but how did they carve the tops in the factory back in the 50's? Did they route the steps and then sand or were the tops hand carved from scratch like a hollow body or a violin?

Just goes to show how few guitars they built back then. The one they use now can do up to 12 bodies at a time.

Tone_Chaser

Senior Member

- Joined

- Jan 24, 2010

- Messages

- 517

- Reaction score

- 258

This has a lot of good information.

[ame=http://www.youtube.com/watch?v=ax0ZFIl_o2w]Build a 59 part 3B - YouTube[/ame]

[ame=http://www.youtube.com/watch?v=ax0ZFIl_o2w]Build a 59 part 3B - YouTube[/ame]

crompo

Senior Member

- Joined

- Apr 7, 2010

- Messages

- 928

- Reaction score

- 1,378

I used an "overhead" setup - router mounted above in a jig and move the body under it rather than using the router (by hand) on top of the templates when attached to the body.

I have heard - and could imagine - that when using the router by hand on top of the templates, there is a chance that the router might "rock" or tip gouging the maple.

Especially with the smaller templates.

Any way - this is how i did it and it worked perfectly.

NOTE the use of feeler gauges and the set stop on the router to get the 1/16" steps exact.

Wayne

http://www.mylespaul.com/forums/luthiers-corner/301297-59-build-2011-2012-a.html

I have heard - and could imagine - that when using the router by hand on top of the templates, there is a chance that the router might "rock" or tip gouging the maple.

Especially with the smaller templates.

Any way - this is how i did it and it worked perfectly.

NOTE the use of feeler gauges and the set stop on the router to get the 1/16" steps exact.

Wayne

http://www.mylespaul.com/forums/luthiers-corner/301297-59-build-2011-2012-a.html

robertoa1a

Senior Member

- Joined

- Jun 27, 2013

- Messages

- 836

- Reaction score

- 397

the edge is under cut (recarve) and goes below the edge of the binding. The pickup area is more flat. don't round that area off or the pickup rings will end up bending around like the modern !'s.

crompo

Senior Member

- Joined

- Apr 7, 2010

- Messages

- 928

- Reaction score

- 1,378

The total thickness of the top is 5/8" - or 10/16".

The way i do it is everything in 1/16" of an inch.

What i mean is this:

The body binding is 1/4" tall - so when the binding channel is cut (after the top is shaped) approx 1/16" is into the mahogany so 3/16" of maple is required at the body edge

So the edge of the maple top on the body sides after routing using the first large template should be 3/16".

Then 7 more steps at 1/16" using the templates (you also cut a 1/16" step after you remove the final smallest template) which gives you a total of 10/16" or 5/8".

Before you start using the templates your maple cap needs to be 5/8" thick minimum but can be and should be a bit thicker.

My top was 7/8" but i planed it down once attached to the body to just over 5/8" prior to carving the top.

As a guide - i would make sure that the thickness of the top before using the templates is approx 1/16" greater than 5/8" to give you some room to move.

Measure the steps as you go to make sure you are close to 1/16" for each.

In this pic:

3/16" maple edge and seven 1/16" steps cut = 5/8"

Does that make sense ?

Look at the pic's and you will be able to see what i mean - i hope !

Your best bet is to read and read to make sure you get what is going on before you even start cutting.

The router jig is just made up to suit my router so you'll have to make one that suits your router and the router bits that you have.

Obviously making it tall enough and deep enough for the LP body to fit under and through.

Wayne.

The way i do it is everything in 1/16" of an inch.

What i mean is this:

The body binding is 1/4" tall - so when the binding channel is cut (after the top is shaped) approx 1/16" is into the mahogany so 3/16" of maple is required at the body edge

So the edge of the maple top on the body sides after routing using the first large template should be 3/16".

Then 7 more steps at 1/16" using the templates (you also cut a 1/16" step after you remove the final smallest template) which gives you a total of 10/16" or 5/8".

Before you start using the templates your maple cap needs to be 5/8" thick minimum but can be and should be a bit thicker.

My top was 7/8" but i planed it down once attached to the body to just over 5/8" prior to carving the top.

As a guide - i would make sure that the thickness of the top before using the templates is approx 1/16" greater than 5/8" to give you some room to move.

Measure the steps as you go to make sure you are close to 1/16" for each.

In this pic:

3/16" maple edge and seven 1/16" steps cut = 5/8"

Does that make sense ?

Look at the pic's and you will be able to see what i mean - i hope !

Your best bet is to read and read to make sure you get what is going on before you even start cutting.

The router jig is just made up to suit my router so you'll have to make one that suits your router and the router bits that you have.

Obviously making it tall enough and deep enough for the LP body to fit under and through.

Wayne.